Bridges & Highway Structures

Highways England Design Manual for Roads and Bridges document CD 357 Bridge expansion joints, specifically sets out the requirements for the design and specification of expansion joints for use in highway bridge decks. It also provides supporting advice on the selection, installation, management and maintenance of various types of expansion joints.

This important UK Highways Engineers Guide states:

“Bridge deck expansion joints can be installed at the transverse joints between the end of the bridge deck and abutment ballast wall, or between adjacent decks in non-continuous multi-span structures.

Expansion joints can accommodate thermal and other movements that occur at the ends of the deck, while providing a level, skid-resistant running surface, capable of supporting the required traffic loads, and managing the drainage of surface or sub-surface water to avoid leakage through the joint.

A variety of proprietary joint types are available to suit different structure types and movement ranges.

Expansion joints, and their constituent components, generally have a working life significantly shorter than the design working life of the structure itself, hence thought needs to be given at the design stage of how the joints are to be maintained or replaced, while minimising delay or disruption to road users.

The generic expansion joint types covered by this document are described in Appendix A. of CD357.

The Guideline for European Technical Approval applicable to bridge deck expansion joints, ETAG 032 [Ref 9.N] is discussed in Appendix B, along with the Declaration of Performance for each of the generic expansion joint types referred to in Appendix A.” (as well as their equivalent in BD 33).

The generic types of bridge deck expansion joints that are listed in the guide include:

Part 2 – Buried expansion joint Type 1 – Buried joint under continuous surfacing Part 3 – Flexible plug joint Type 2 – Asphaltic plug joint Part 4 – Nosing expansion joint Type 3 – Nosing joint with poured sealant and Type 4 – Nosing with preformed compression seal Part 5 – Mat expansion joint Type 5 – Reinforced Elastomeric Part 6 – Cantilever expansion joint Type 7 – Cantilever comb or tooth joint Part 7 – Supported expansion joint Not covered Part 8 – Modular expansion joint Type 6 – Elastomeric in metal runners

We should be clear to say here that the provision of these complete mechanical bridge deck expansion joint systems is outside of the scope of Emseal joint sealing systems. However, where appropriate for many of these systems, their service life can often be increased, potential structural damage avoided, as well as lengthy road closures and costly replacement being prevented, by using the Emseal BEJS system to make ‘shorter’ term / intermediate or perhaps ‘temporary’ holding repairs by replacement of just the central movement section of these joints.

All Bridge Structures Can Benefit from Emseal Joint Systems

This ‘temporary’ period may in fact be for several years as evidenced by our experience in the USA and Canada, where this concept began as an innovation from several state DOT’s (Departments of Transport). This approach has now also been picked up by several Highways Engineers and their term contractors in the UK, as it provides a fast and very cost-effective solution to replace deteriorated central sealing areas of such joint systems. This ensures that watertightness is maintained and the rest of the structure is protected, whilst future major repairs and overall replacement can be fully developed, planned and costed, including all of the deeply unpopular closures and delays required for this sort of major structural works, right across our roads network.

In addition to bridge deck expansion joints, the Emseal BEJS solution has also proven to be the ideal approach for the more permanent sealing solutions for several other types of movement joints on bridge structures. This is especially true when extruded sealants and other traditional sealing systems are not suitable or have failed. Importantly in all of these refurbishment and resealing situations the responsible bridge and structural engineers must make their own individual decisions e.g. through evaluation and assessment of the alternative options. The engineers must then make the decision on the most effective approach to try and select the most appropriate engineered solutions for their specific bridge joint sealing requirements.

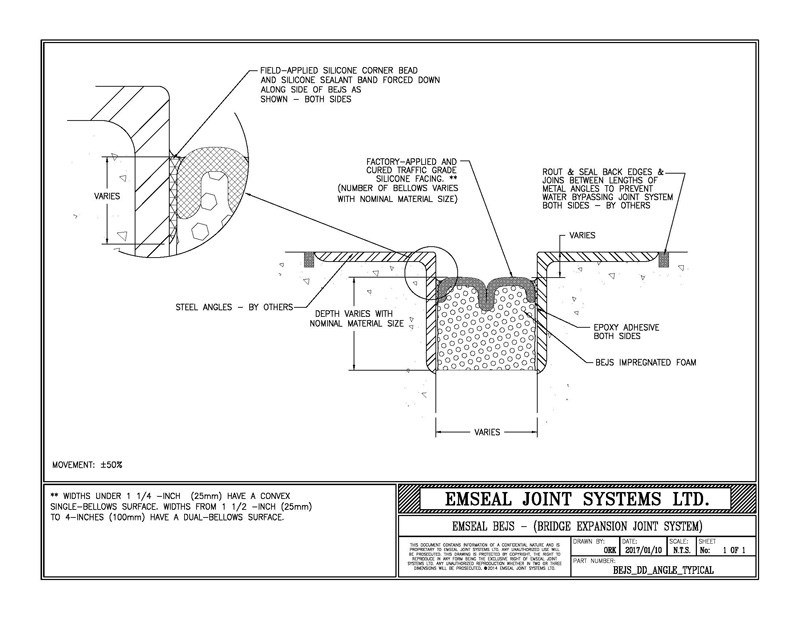

Emseal CAD Drawing : Bridge Joint Repairs: Asphaltic Plug

Emseal CAD Drawing: BEJS Nosing - Section Replacement

Interestingly our involvement in bridge joints was once totally involved with refurbishment projects, but recently there has been significant adoption for new works as well. For example in the UK we have recently been involved in providing the Emseal BEJS system to solve several difficult joint sealing situations for Parapet wall joints, specifically where high joint movement capabilities were necessary but where there were variable existing joint widths. Another recent requirement was for sealing Wing wall joints prior to backfilling and that were subject to a joint movement capability that was potentially 100% of the joint width; these had to be sealed, backfilled and then remain securely watertight and support the extended service life required of these important structures.

NCC and Emseal have recently produced a UK version of the ‘BEJS System Information Guide’ that was developed by Emseal with American and Canadian Bridge Engineers, as a guide to support and assist engineers and contractors to securely seal all kinds of movement joints using the Emseal BEJS System. The original American version has proven particularly useful from the design office to site for Main Contractors on new construction projects, as well as for the many different City, State & Federal Agencies and their Bridge Maintenance Contractors, all working to keep the traffic moving!

This practical and informative guide contains a lot of useful information and practical guidance for in making the right decisions on every site. These important decisions include easy checks for determining the right BEJS system sizes to order and install, then a step-by-step guide to the installation of the BEJS sections on site. This BEJS guide can be viewed and/or downloaded in PDF format here: View/Download

This UK version of the BEJS Guide is also available in A4 printed hard copy on request, for a copy just email us at: Sales@EmsealServices.co.uk

For any specific bridge movement joint requirements you can also contact NCC to provide support and advice to help you to solve bridge deck expansion joint leaking and maintenance problems, as well as to find solutions for any other expansion joint sealing requirements Take advantage of the proven Emseal systems performance on your bridges and highway structures, please call 01257 266696 or you can email: technical@emsealservices.co.uk

Incidentaly in North America, the Emseal BEJS systems have had such great success in solving many difficult issues in recent years that the company has now also formed the Emseal Bridge Division with a dedicated support team that are now also working with NCC to support bridge expansion joint issues on highway structures throughout the UK. The Emseal Bridges Division also has a dedicated USA website that contains a lot of additional and hopefully very useful, bridge joint related information that you can view here: https://www.emseal.com/bridge-expansion-joint-division/